So the first two dozen will be the same elongated copper stamping (got them at Metalliferous) that I did the samples in .

The hard part is always cleaning and prepped - My favourite tool is the dremel with the split mandrel and sandpaper.

I laid them out and started cleaning

I made my way down the line with the dremel - I only clean one side as that is for the stamping side - no sense cleaning the other till your ready to finish - and once finished cleaning with the dremel and sandpaper- I donned my rubber glove and finished them with steel wool

the rubber glove was to make sure I didnt leave any fingerprints and oil on the blanks. Not just so you have a clean surface - any oils may create a resist to the ferric chloride as well.

Once finished they were ready for stamping

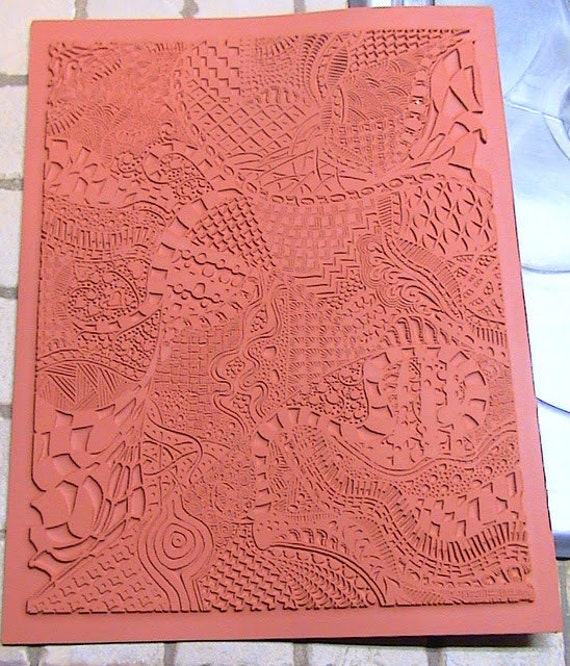

I prepped the rubber stamp (available on etsy - see side bar)

(this is stamp #2 pattern) I took the stazon and made sure the pad was properly wet with ink and dabbed it onto the stamp area I wanted to work - I did not do the whole stamp as it would dry quickly and be wasted -the white in this case - not sure if it really matters what color you use as the ink dries quickly and is taken off with acetone. And my micheals only carries the white for some reason.

(this is stamp #2 pattern) I took the stazon and made sure the pad was properly wet with ink and dabbed it onto the stamp area I wanted to work - I did not do the whole stamp as it would dry quickly and be wasted -the white in this case - not sure if it really matters what color you use as the ink dries quickly and is taken off with acetone. And my micheals only carries the white for some reason.

I place the clean side down carefully - pressed down evenly - placed one finger at end and pressed down which raises the other end and again carfully grabbed the sides and set to the side to dry . I was trying to keep the pairs relatively close in pattern as I stamped - but they are not identical - that is the randomness (is that a word) of the zentangle. Because I wanted to use the same general area I again dabbed the ink onto the stamp and just kept going.

Some of the stamping was pretty darn close to being the same

Hard to see with the light reflection but all two dozen stamped and now ready to go into the etching solution.

It takes only a minute or two for the staz on to dry which is great - makes it easier to handle

I prepared so that each tape would hold the pair - when its a single metal bracelet it suspends across the container - but because these are smaller the weight bends them in the center so you want them to be balanced and not fall to the center of the container- just enough so they are suspended on the surface - I could probably fix this by adding some sort of support on the tape or making a floating double sided tape on some foam - which I am looking around for - havnt had any in my shipping /packing lately - my current set up holds 6 sets at a time - need to get another large glass container and get out my other hot plate.

anyway - only 3 more batches to go - I have to stay up to at least 11pm tonight and take them out and put them into baking soda to stop the etching process - and dry them off - while the first batch is in tomorrow Ill start to finish - Yawn - 1-1/2 hours to go ........ so I will show tomorrow the results of batch 1

\

I LOVE THIS STUFF

I LOVE THIS STUFF