Revision Date: Nov. 24, 2012

Will update as I go along

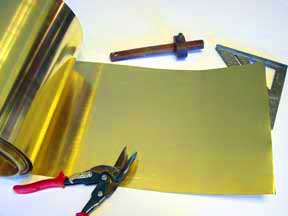

Materials you will need

26 g Wire - for use with the beads- I am using Nickel Silver

now you do not have to use this - you can use any 26g wire

I chose nickel silver for economy, that it does not tarnish as much as silver and was easy to get in large spools. 26g as it is thin enough to go through most of the standard pressed bead holes.

14 g Wire - for base collar

14g Nickel Silver

Yes I ordered waaaaaaaaay too much but hey you never know when you want to make a 1000 necklaces

I also find if I order larger quantities it eventually saves on shipping (I think somewhere around 2019 I'll break even )

I got the wire from R. J. Leahy

http://www.rjleahy.com/Store/wire/kwi.htm

You can use Artistic Wire as well - I just find it a bit softer but will work just as well and most have this in their craft stock

You can use any wire you wish - silver, copper, brass to give various effects

Dowels or Knitting Needles - fairly large - or maybe even a couple of pens can work -

You want something round - that is not going to break as you twist the wire

Your end result will be a piece of twisted 14g wire approx 18" long- one end with a loop

and the other with two loose ends - one that you make a hook and one that you can design an open swirl

so that when you put it together the hook connects to the loop and the swirl hangs below.

This is your tBASE to work on

STEP 1 - BASE

Cut approx 3.5 ft of 14g nickel silver wire (if you have too much you can cut down and adjust - depending upon how big you need it )

fold in half over first dowel

then just wrap the ends over the second dowel (you dont have to do but one wrap) and I alternate - one going one way - one going the other

you dont have to be exact as we will be modifying the ends

Hold the dowel with the loop in your hands and stand on the second dowel

start twisting.(one direction only ) twist, twist till you get an even twist from top to bottom - the dowel tends to untwist when you stop so let go and see if it becomes too loose and then tighten up till your satisfied.

take out the top dowel and you have your loop end

take out the bottom dowel - these end looks fuggly and we will fix these but its time to measure

I like to just bring it around my neck and judge where I want to have the center fall - then I will cut back and make my hook and swirl. Here is where you judge for longer, shorter, tighter etc.

Here we finesse the wire ends

make sure you round out your necklace around your neck to see where they join - this helps in the end process

sometimes I see one end looks more like the hook or one end is longer and is best for the swirl

trim and curve for the hook and hook it into the loop - there should be enough tension to pull and keep it sort of tight (we can work more on it later)

take the long end and create your swirl

we now have our base

(try different lengths for different effect of where its going to lay around your neck

STEP 2 - ADDING THE BEADS

Cut a piece of your 26g approx 3 ft - This I can control and is easier to work with but that is up to you.

I like to attache one end first before I start adding my beads so they do not fall off the end or if I pull the wire from the table all the beads fall off (yup it happened)

So just take one end and do a simple wrap starting around the loop end

Here may be the hardest part of all - choosing your beads and colors

sometimes I start with all the same bead - like leaves and wrap all around

then second wrap will be next bead - like flowers and work them between the leaves

then add other mixes etc... till its full

My bead bag

I like the dagger type , leaves, drops and the little pressed flowers

feed your beads onto the wire - you dont have to fill the wire - just a few inches at a time

the process is put bead to base - wrap wire to front, bring wire up

bead to base wrap wire behind and then to front of new bead

bead to base wrap wire behind and then to front of new bead

you continue till you fill your first layer - sort of a backgrouind and then we add more beads

try not to kink your wire - be carefull of the loose end as you flip it around and can poke you ( might want to wear your safety glasses

more to come

looks really cool

looks really cool

Brass

Brass aluminum

aluminum bronze

bronze aluminum

aluminum  gold coloured aluminum

gold coloured aluminum

(mine only has wing nuts I like the blue anodized surface and the twist knobs)

(mine only has wing nuts I like the blue anodized surface and the twist knobs)